Process development & implementation

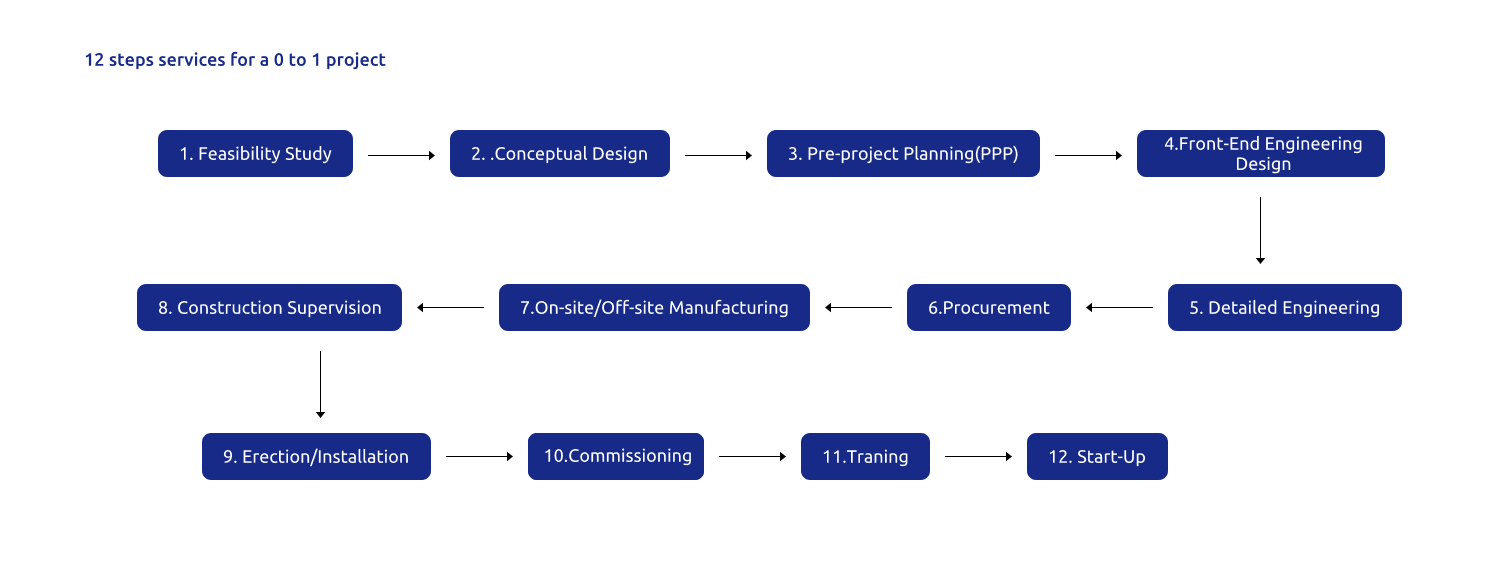

Contact a services specialistTianli’s chemical process design aims to formulate a manufacturing process that enables the production of chemicals or similar products in a safe and cost - effective manner. The process design encompasses the following steps:

1. Conceptual design ; 2. Process development ; 3. Comprehensive design ; 4. Construction of prototype ; 5. Pilot test ; 6. Evaluation & optimization ; 7. Scale-up ; 8. Production Operation ; 9. Quality control checks

Chemical engineers and process technicians are dedicated to understanding the chemical reaction mechanism and devising a plant or refinery layout to achieve optimal production output. Moreover, they endeavor to optimize the processing conditions to maximize operational efficiency.

The overarching objective of chemical process design is to develop a cost - effective and safe process for both workers and product consumers. The processes must yield high - quality products at a high production rate. Engineers and technicians enhance process efficiency and environmental sustainability by analyzing and improving existing processes.

Feasibility study & FEED

Contact a services specialistAt Tianli, innovative thinking collaborates closely with the latest process technology to offer pioneering Front-End Loading (FEL) and Front-End Engineering Design (FEED) services.

As an expansion of Tianli’s engineering design proficiency, our FEL and FEED services are essential for establishing a framework to ensure project completion on schedule and within budget.

Acknowledging the significance of providing precise parametric information prior to project initiation, Tianli utilizes the most advanced process technology available in the market, along with a variety of proprietary equipment, to minimize and assess overall costs. Energy - saving measures and waste reduction catalysts are also adopted to optimize quality and productivity. Moreover, every project is evaluated using the latest commercial information to accurately estimate construction expenditures.

Our engineers draw on decades of experience to recommend a feasible and cost - effective approach during the FEL stage and to propose detailed concept and design work during the FEED stage. We are meticulous and innovative when exploring investment requirements, production strategies, and site alternatives. We provide accurate evaluation and analysis to support decision - making, as well as well - defined system configurations.

Tianli provides FEED Packages with quality cost estimates that fall within the 15% - 30% range of the final cost upon the client’s request, including a Level 3 project schedule. For clients or operators who prefer to tender the equipment and packages during the FEED stage, we can supply the necessary details regarding key equipment data sheets, piping and instrumentation diagrams, instrumentation requirements, as well as general overviews on instrumentation, automation, and control systems.

Basic & Detailed engineering

Contact a services specialist- BASIC & DETAILED ENGINEERINGTianli’s engineering endeavors concentrate on the design across all specialties, namely Civil Engineering, Structures, Clean Rooms, Air Systems, Auxiliary Installations, Fluids, Dust Collection, Electricity, Access Control, Fire Fighting, Sizing of Pharmaceutical Process Technology Installations, Packaging, and Legalization. We present a comprehensive service portfolio that encompasses EPC (Engineering, Procurement, and Construction), EPCM (Engineering, Procurement, Construction Management), construction management, audits and consultancy, project executions, after - sales services, training, and maintenance contracts.

![BASIC & DETAILED ENGINEERING]()

- BASIC ENGINEERINGThe basic engineering design phase is typically linked with an economic and financial feasibility study. For one or two solutions that prove to be the most appropriate in the preceding phase, detailed design elements are furnished. These include field investigations, particularly those of a topographical, geological, geotechnical, hydrological, and hydraulic nature. Within the engineering project, details regarding the unit costs of materials and different construction phases are provided. This process aims to yield a more realistic project cost estimate.

![BASIC ENGINEERING]()

- Documentation for Basic Engineering Project1.Design bases and criteria (for validating and verifying the Conceptual Engineering)

2.Definition of the final functional requirements

3.Flow Diagrams of Principal and Auxiliary Processes (covering personnel and materials)

4.Final designs inclusive of calculations (for all specialties involved in the project)

5.Description of the process and philosophy underlying the final Operation and Control

6.Final Requirements for Complementary Goods and Services

7.Final major equipment specifications (As - Built documentation and engineering plans for each system)

8.Piping and Instrumentation Diagrams

9.Implementation Layout

10.Specifications of construction scope by discipline

11.Specification sheets for instruments, equipment, and inputs

12.Detailed layouts

13.Control system specifications

14.Control system architecture

15.Cost assessment for the entire project (±15%) - DETAILED ENGINEERINGA detailed engineering project consists of a set of documents derived from the Basic Engineering. It encompasses all construction details by discipline, such as Civil, Mechanical, Process, Electric, Telecommunications, Instrumentation and Control, and Computer Systems. These details must be approved for construction purposes. This process serves to generate a precise project cost estimate. Our objective is to deliver an engineering project outcome with no time or cost deviations.

![DETAILED ENGINEERING]()

- Documentation for Detailed Engineering ProjectProcess discipline: piping and instruments diagram (PID), process data sheet, etc.

Piping discipline: pipeline layout, isometric piping drawing (ISO drawing), etc.

Piping material discipline: valve specification, pipeline material sheet, etc.

Mechanical discipline: equipment assembly drawing, equipment installation detail drawing, etc.

Instrument and automatic control discipline: instrument cable list and wiring diagram, DCS/PLC system configuration diagram, etc.

Electrical discipline: electrical equipment layout, explosion-proof area division diagram, etc.

Civil discipline: foundation structure drawing, steel structure design drawing, etc.

HVAC discipline: duct layout and equipment positioning drawing, HVAC equipment data sheet, etc.

Water supply and drainage and fire protection discipline: fire protection system design drawing, sewage treatment system design documents, etc.

Safety and environmental protection discipline: environmental protection facility design documents, occupational health and fire protection assessment report, etc.

General layout and transportation discipline: general layout, vertical design drawing, etc.

Project management

Contact a services specialistProject management

Erection, installation & commissioning

Project management supervision services:

Tianli offers on - going plant services including support, full - service plant engineering, reliability, turnaround, outage and after - sales services worldwide.

In the construction of projects, systems and works, the application of engineering does not end with the delivery of project design drawings to the owner or developer. The production of a competent engineering design does not assure the owner that the project will be safely constructed in accordance with the sound engineering principles and practice. Design of projects, systems and works, is an initial phase of engineering; supervision of construction is another, equally important phase. Engineering supervision of construction is required to ensure, among other things, correct interpretation and application of the design, and of the engineering principles which are expressed in it.

In addition, all engineering details cannot be totally addressed in the design phase—even in the most comprehensive drawings and specifications. Accordingly, it is necessary for engineering judgments to be made during the course of construction. Tianli's Erection and Commissioning Supervisory team are capable of doing that with a high level of competency and field experience. Tianli also takes up erection and commissioning assistance for the project on a per - diem rate basis besides lump sum or part of the EPC contract.