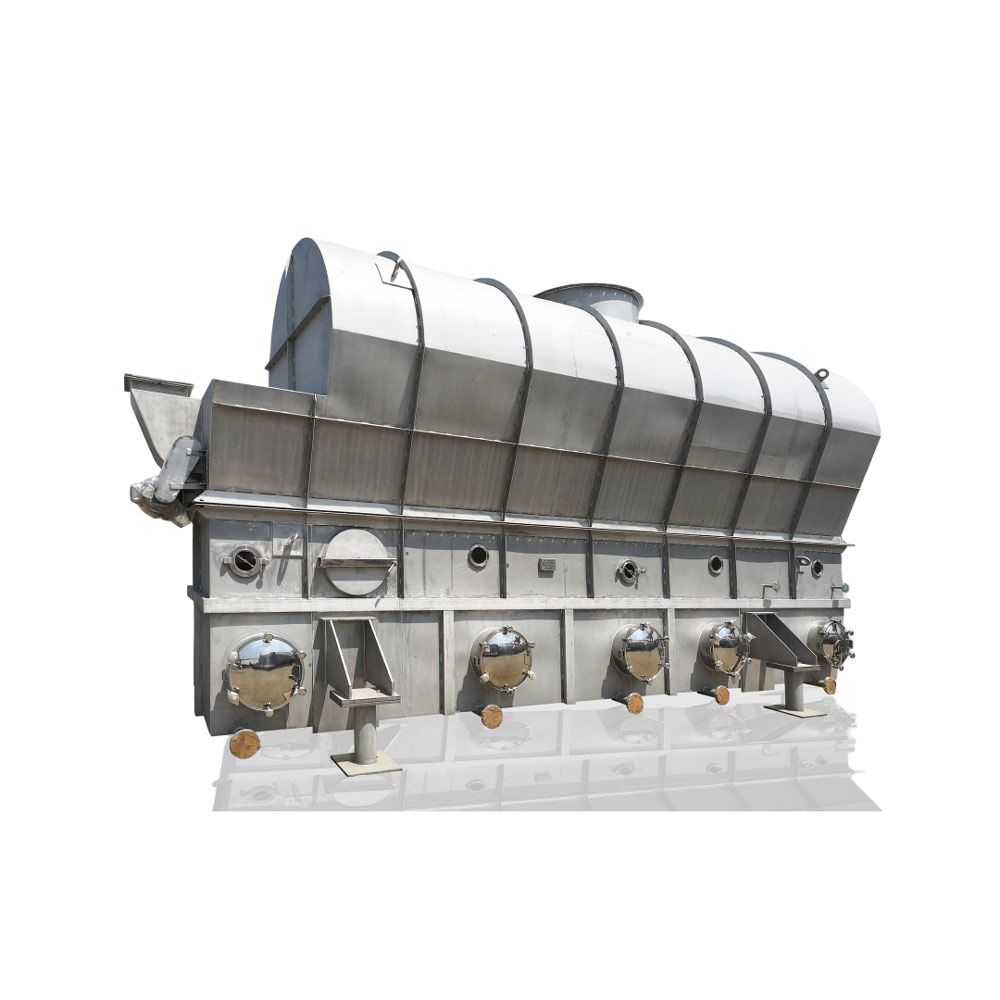

Steam rotary drying technology for ammonium chloride.

Contact us

Core advantages compare to traditional fluid bed dryer approach:

(1) Energy saving: The cost per ton of product is reduced by $ 15.57 (measured by steam: $ 130/t, electricity: $ 0.5/kWh).

(2) Environmental protection: The amount of tail gas is reduced by order of magnitude, and the free ammonia emission is reduced by 14.4t/a (calculated by the free ammonia content of the dry tail gas of 50mg/m3); Lower water consumption for dust removal。

(3) Operating environment: Negative pressure operation, less ammonia smell, cleaner drying workshop; No high-power fan, less on-site noise。

(4) Operational stability: No need for block discharge device, no fluid bed dryer clogging, higher automation level.

(5) High flexibility in operation: Unit energy consumption is basically the same under different load conditions;

(6) Easy maintenance: The rotary dryer is a detachable structure, which is convenient for maintenance and overhaul.

Our steam rotary dryer production site