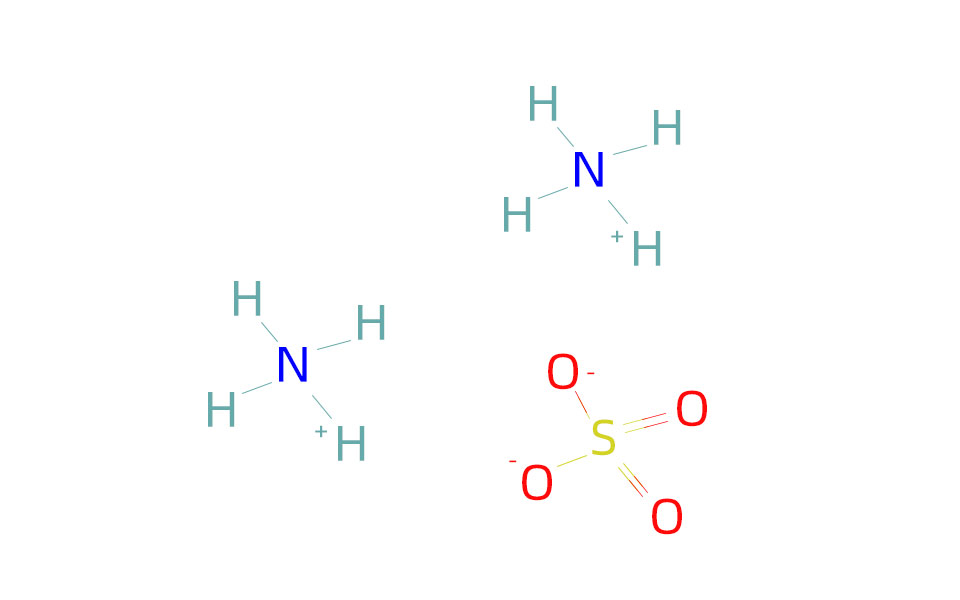

Neutralization method of ammonium sulphate

Contact us

At present, ammonium sulfate mainly comes from by-products or waste gases discharged in industrial production. It is absorbed by sulfuric acid or ammonia water (for example, sulfuric acid absorbs ammonia in coke-oven gas, ammonia water absorbs sulfur dioxide in flue gas from smelters, ammonia in caprolan production, and sulfuric acid waste liquid in the production of titanium dioxide by the sulfuric acid process), then crystallized by using an ammonium sulfate evaporation crystallizer. There is also the gypsum method for producing ammonium sulfate (using natural gypsum,phosphogypsum, ammonia or carbon dioxide as raw materials). It is obtained by neutralizing ammonium hydroxide and sulfuric acid, followed by crystallization, centrifugal separation and drying.

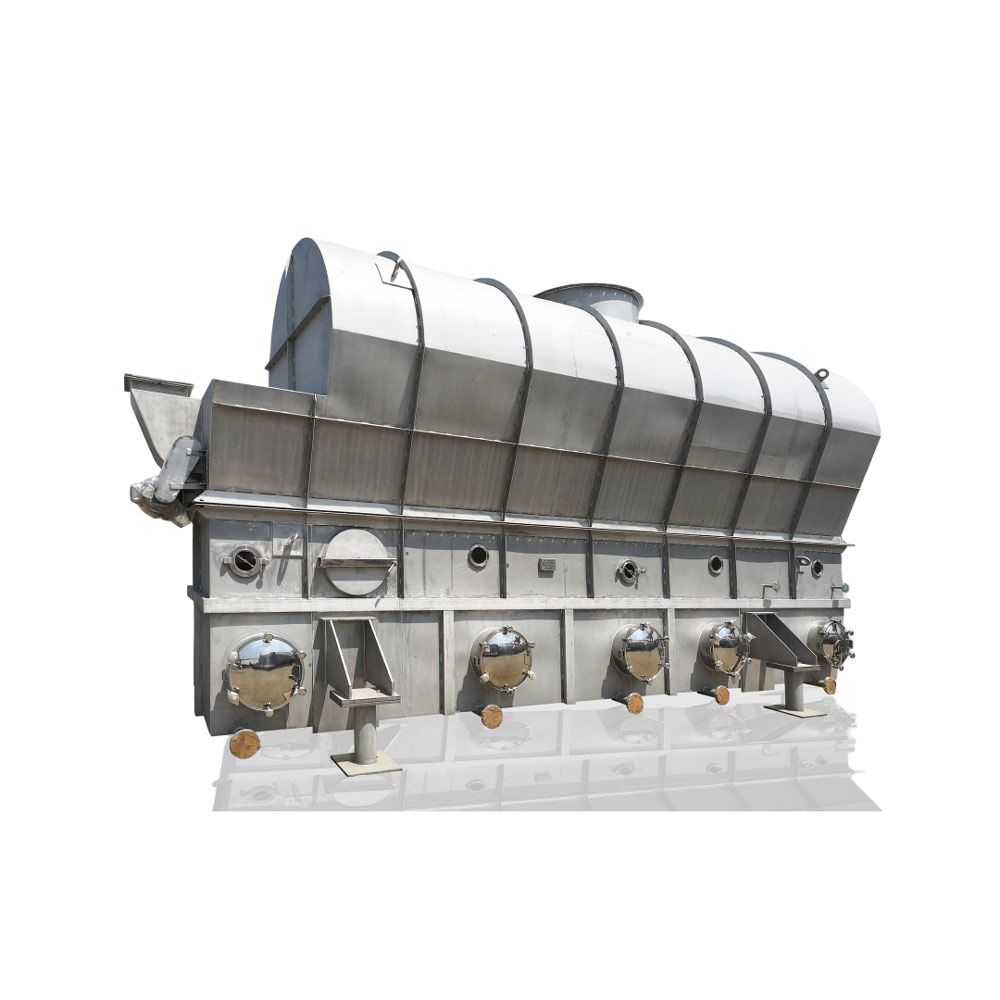

In the production of ammonium sulfate by the neutralization method, ammonia and sulfuric acid react in a saturated crystallizer (under vacuum or normal pressure) to generate ammonium sulfate crystals. After being separated by a centrifuge and then dried, the product is obtained. The mother liquor is returned to the saturated crystallizer. This reaction is a strongly exothermic reaction, and the heat of reaction is used to evaporate the water brought in by sulfuric acid or deliberately added to control the temperature. In the normal pressure saturated crystallizer, a large amount of air can be blown into the reaction materials to remove the heat of reaction. The method of using sulfuric acid to wash ammonia in coke-oven gas or coal gas to produce ammonium sulfate also belongs to the neutralization method.

The advantages of the neutralization method are that the process is mature, the raw materials are easy to obtain, the product has high purity, and the energy consumption in the production process is relatively low.