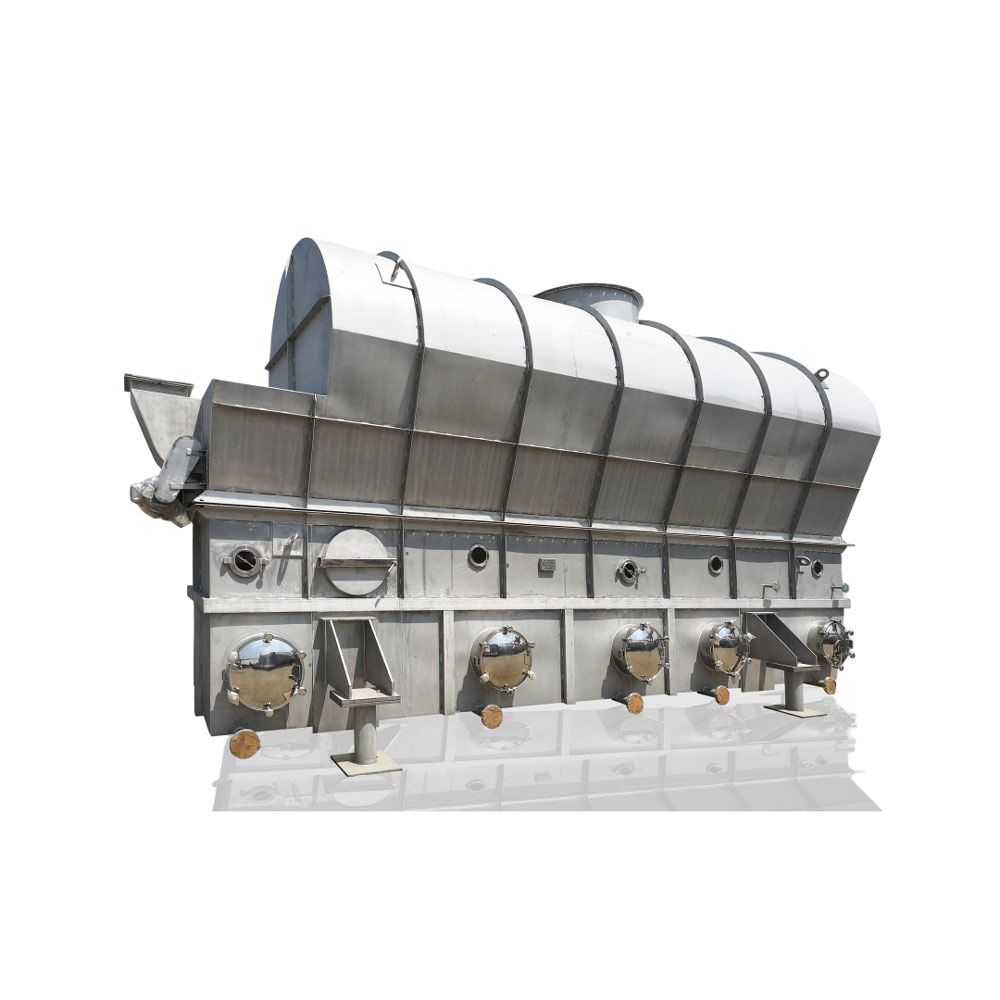

Our drying system with a fluid bed dryer with built-in heat exchanger as the core adopts the drying process of nitrogen closed-circuit circulation protection. Firstly, the system conducts nitrogen replacement by introducing nitrogen into the drying system through the replenishment port. After confirming that the oxygen content is lower than 3%, the system is heated up to the start-up temperature. Then, the wet ABS powder filtered by the centrifuge is added to the internally heated fluid bed dryer for drying. The nitrogen is pressurized by the blower and heated by the steam heat exchanger before entering the wind chamber at the bottom of the fluid bed dryer and then passing through the air distribution plate to enter the bed layer. During this process, the inlet air temperature and air volume are controlled to gradually build up the bed layer and make it fluidize and be evenly distributed within the fluid bed dryer. After the bed layer is established, normal production is carried out according to the designed working conditions.

To ensure the quality of the finished ABS products, the powder unqualified products collected by the cyclone dust collector are returned to the fluid bed dryer with built-in heat exchanger to continue the drying process, and the materials collected by the bag dust collector are regarded as qualified products and returned to the outlet of the finished products of the fluid bed dryer. The dried qualified products are discharged through the overflow port of the fluid bed dryer and then discharged through the finished product rotary valve.