Coal slime recycling technology

Contact us

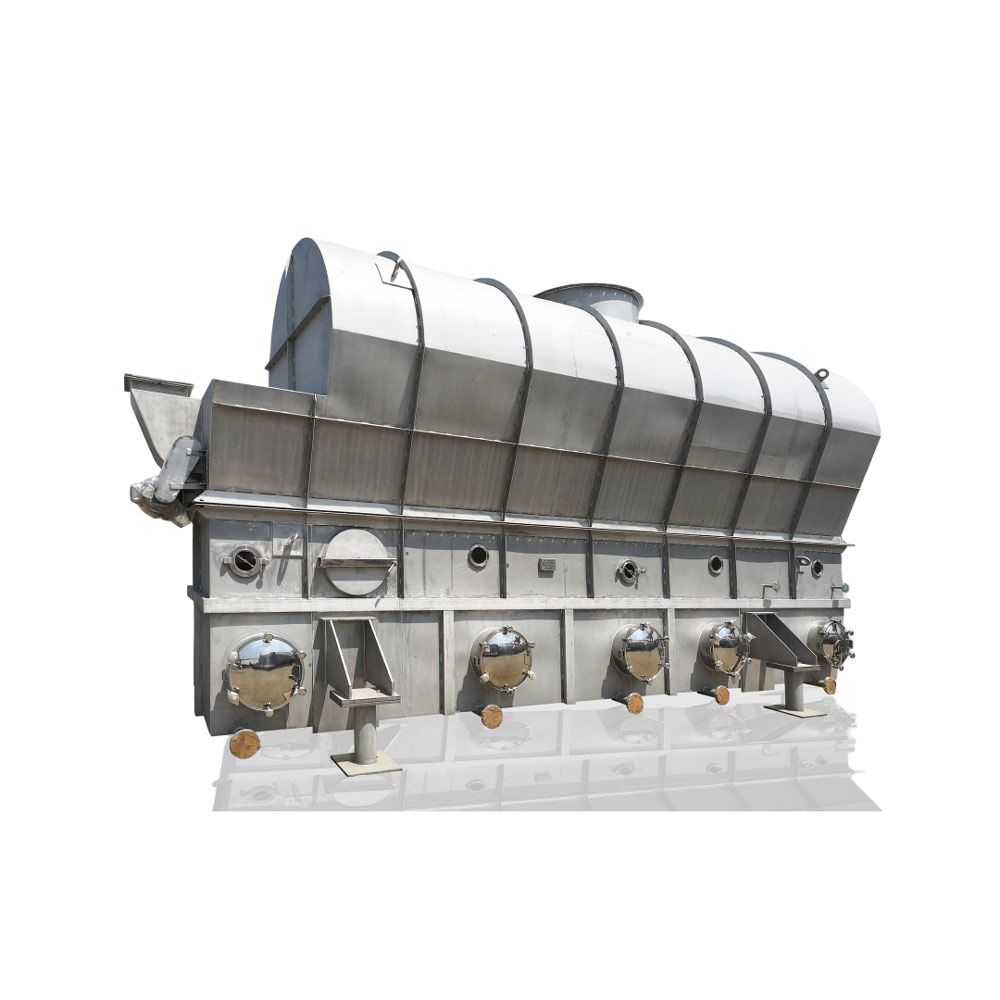

The steam rotary dryer can indirectly dry the wet coal slime, and the drying environment is safe. The wet coal slime enters the dryer through the crushing silo, belt conveyor, and screw conveyor. As the cylinder rotates, it contacts the steam heat exchange tube inside the dryer, performs indirect heat exchange, and gradually moves to the discharge end. The qualified coal slime is discharged from the cylinder, and the moisture evaporated from the coal slime is taken out by the wet gas, and the induced draft fan is purified by the spray tower and heated by the heat exchanger before returning to the steam rotary dryer for recycling. The main equipment used in the low-temperature steam rotary drying process is the steam rotary dryer. This process is a new type of environmentally friendly drying process. Compared with the traditional process, its feature is “steam as the drying heat source”, and the drying process only involves physical drying and mechanical extrusion. The production process no longer generates solid waste emissions, avoiding secondary pollution to the environment. The condensate after the steam works can be recycled to achieve zero emissions.