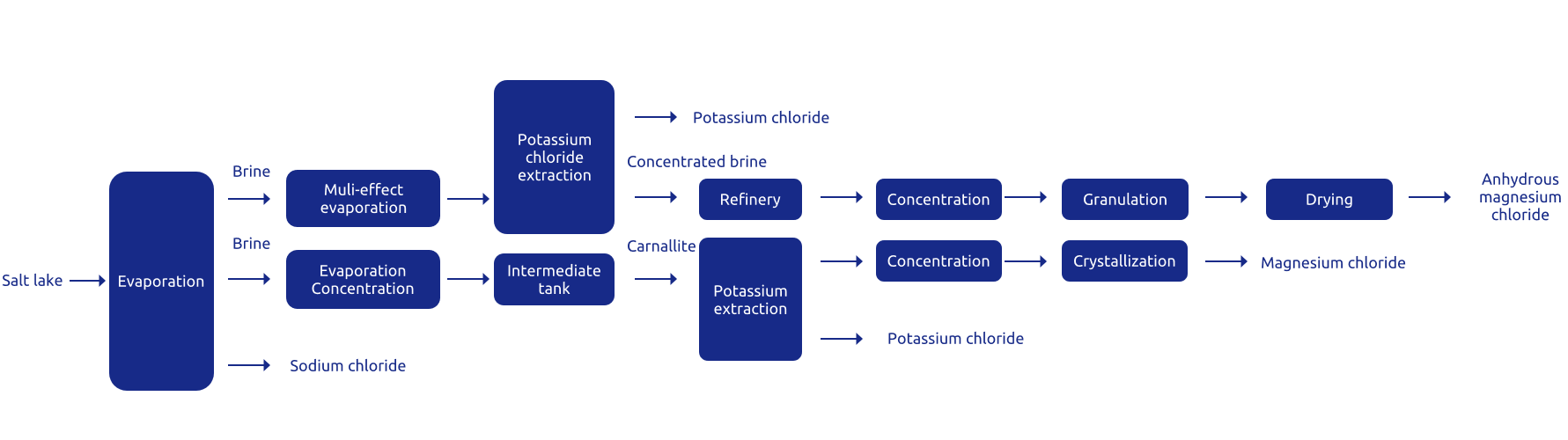

Technology of integrated metal magnesium project using brine from salt lake

Contact us

Typical technical indicators of anhydrous magnesium chloride using Tianli EPC service

1.Content of sulfate ions≤20ppm, content of boron ions≤1ppm in the refined brine

2.After 1st stage dehydration, wet granules discharged from the granulation tower contain ≤5.0 mol of crystal water. Average particle size of the wet granules:0.6 mm, particle size range:0.25 - 1 mm (>94%)

3.After 2nd stage dehydration,particles discharged from air dryer contain ≤2.0mol of crystal water

4.Anhydrous magnesium chloride after 3rd stage dehydration: MgCl2≥95%,MgOHCl≤0.4%, H2O≤0.1%

5.Only production line in the high-altitude areas around the world with a production capacity of 6 tons per hour

New achievements in improving the cost-performance of magnesium metal

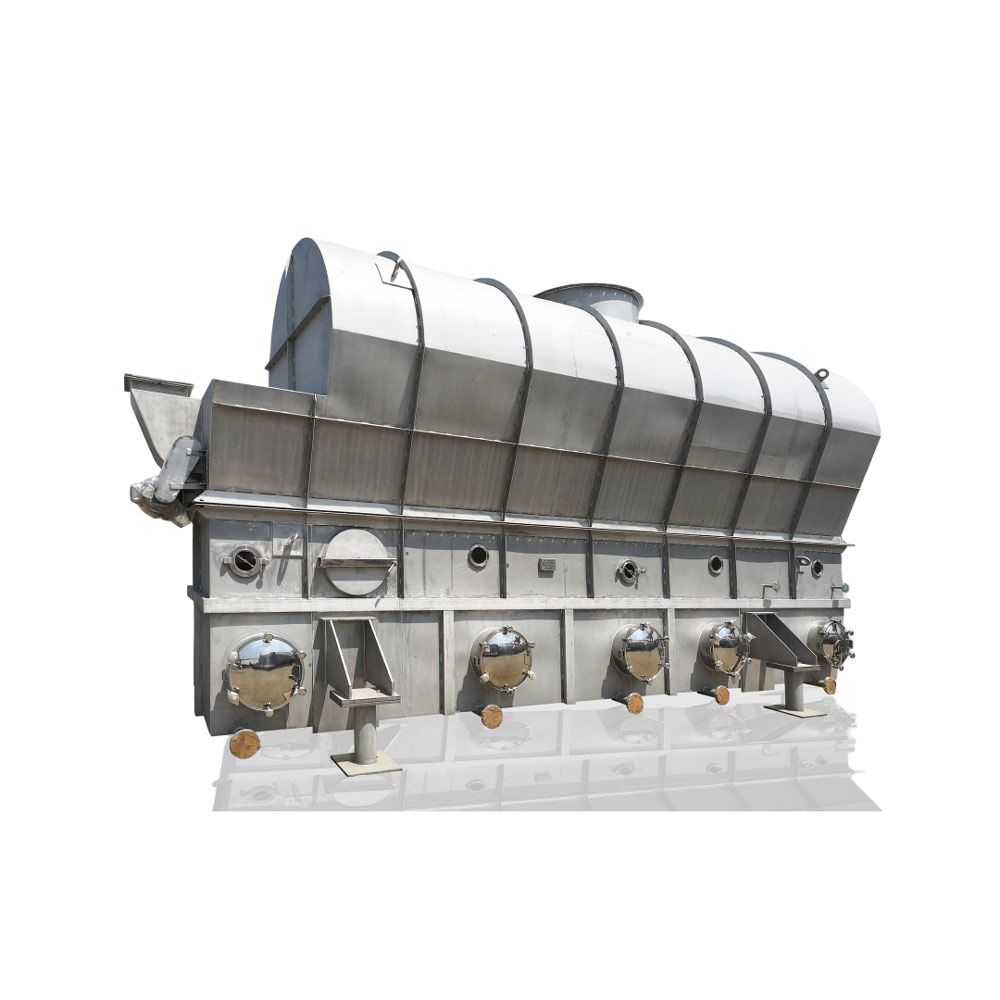

1、Dehydration Technology Innovation: A pressure spray granulation fluid bed dryer is used to simultaneously complete granulation, drying, and reverse reaction, replacing the traditional three sets of equipment: centrifugal granulation tower, air drying, and hydrogen chloride drying. At the same time, make full use of the flash phenomenon of the pressurized magnesium chloride solution at 191°C/4.8 mol, the heat release of crystallization, the waste heat of the drying tail gas and other conditions to preheat and concentrate the 33% magnesium chloride solution. The evaporated secondary steam is used to preheat the hydrogen chloride. The dried anhydrous hydrogen chloride particles at 330°C enter the molten chlorination furnace, saving the production cost of anhydrous magnesium.

2、Electrolysis Technology Innovation: The application of multi-polar cell electrolysis technology and molten chlorination furnace. The multi-polar electrolytic cell has the advantages of low direct current consumption and high chlorine concentration. It is traditionally used for the co-production of magnesium and titanium, and its raw material is the molten magnesium chloride produced during the reduction of titanium sponge. Tianli has explored a multi-polar electrolytic cell suitable for the electrolysis of magnesium in salt lakes. The equipment operates stably, has low energy consumption, and high product quality. The anhydrous magnesium chloride melting and purification system can remove residual moisture and impurities such as basic magnesium chloride in the raw materials, providing molten raw materials for the multi-polar electrolytic cell. The application of these two technologies will increase the concentration and cleanliness of electrolytic chlorine, achieve the chlorine balance of the integrated metal magnesium project, and significantly reduce energy consumption.