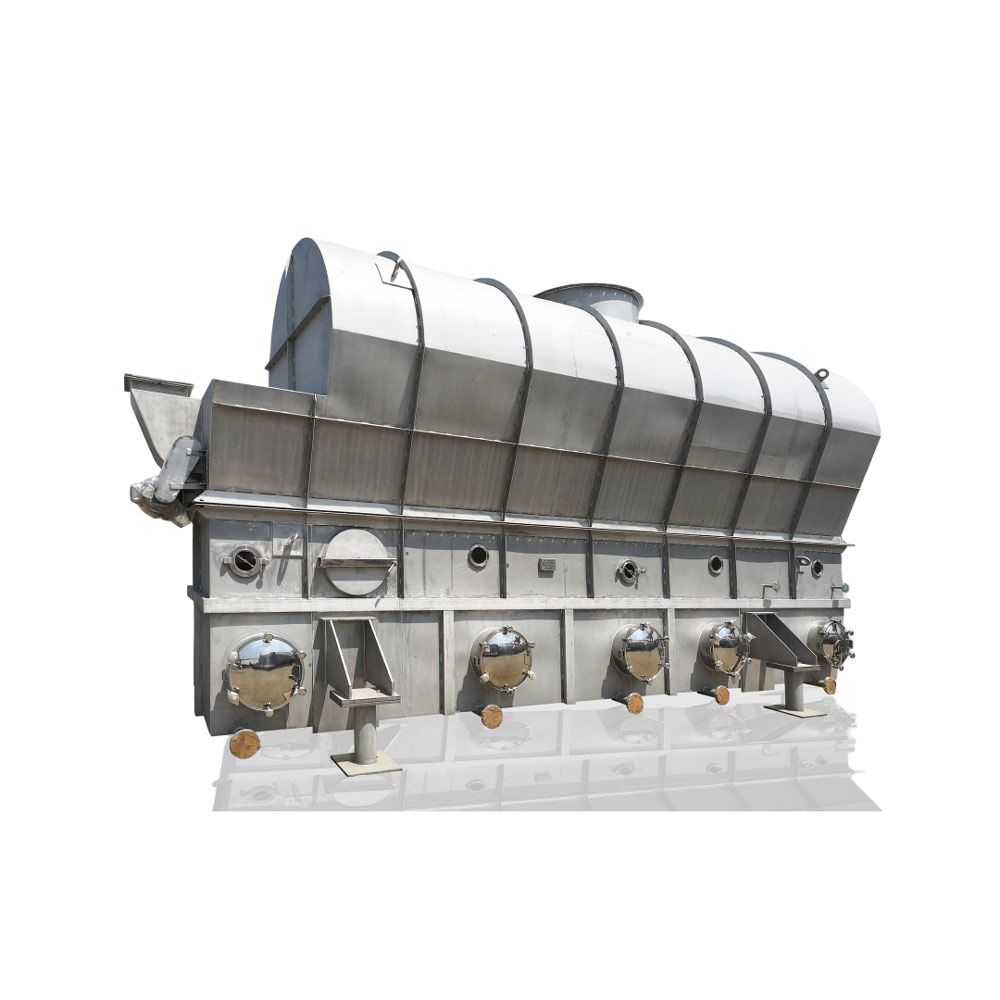

The drying system adopts a closed-loop process with nitrogen protection for drying and cooling. The wet methionine is conveyed from the previous process by the filter screw conveyor to the buffer silo, and then sequentially passes through the twin-shaft conveyor, feed discharge valve, and feed disperser before being added to the fluid bed dryer with in-built heat exchanger. The nitrogen gas comes from the system's nitrogen supplement port, is pressurized by the circulating fan, and heated by the exchanger before entering the bottom air chamber of the drying section of fluid bed dryer with in-built heat exchanger. It then passes through the air distribution plate into the material layer. During this process, the nitrogen is effectively controlled to maintain stable fluidization of the material, and it exchanges heat in the material layer for drying. The dried material enters the cooling section of fluid bed dryer with in-built heat exchanger, where it exchanges heat with the continuously incoming cold nitrogen gas and the heat exchanger in the material layer. The cold nitrogen gas is compressed by the circulating fan, cooled by the surface cooler, dehumidified by the demister, and then enters fluid bed dryer with in-built heat exchanger through the air chamber and air distribution plate. The product cooled to a specific temperature flows out through the overflow port of the fluid bed dryer and is discharged via the discharge valve.

The products discharged from the fluid bed dryer are transported by the conveying equipment and then screened by the vibrating screen. The products with qualified particle size are sent to the methionine cooler while the unqualified ones are sent to the crusher for crushing. The crushed products are then sent to the cooling section of fluid bed dryer with in-built heat exchanger.