Non-ferrous metal ore selection

Contact us

The mined ore is first crushed by the main crusher in the ore dressing equipment. After being crushed to the reasonable fineness, it is evenly sent to the ball mill through the elevator and the ore feeder, and the ore is crushed and ground by the ball mill of the ore dressing equipment.

The fine ore ground by the ball mill enters the next process: classification. The screw classifier uses the principle that the solid particles have different specific gravities and different precipitation speeds in the liquid to wash and classify the ore mixture.

When the washed and classified mineral mixture passes through the magnetic separator, the magnetic substances in the mixture are separated by magnetic and mechanical forces due to the different specific magnetic susceptibility coefficients of various minerals.

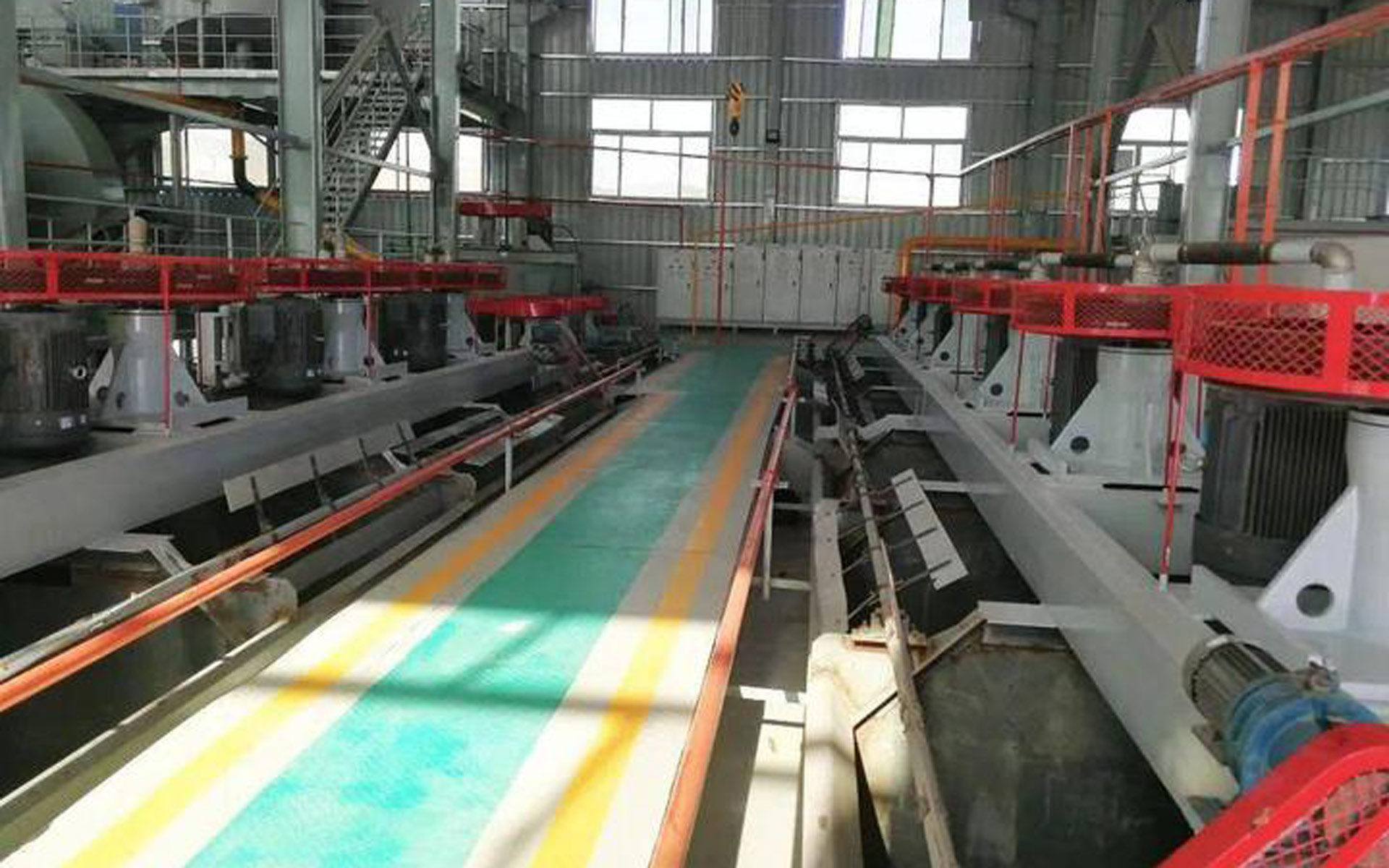

The mineral particles that have been initially separated by the magnetic separator are sent to the flotation machine, and different drugs are added according to different mineral characteristics to separate the desired minerals from other substances.

After the needed minerals are separated, because they contain a lot of water, they must be initially concentrated by the concentrator, and then dried by the dryer to obtain dry minerals.