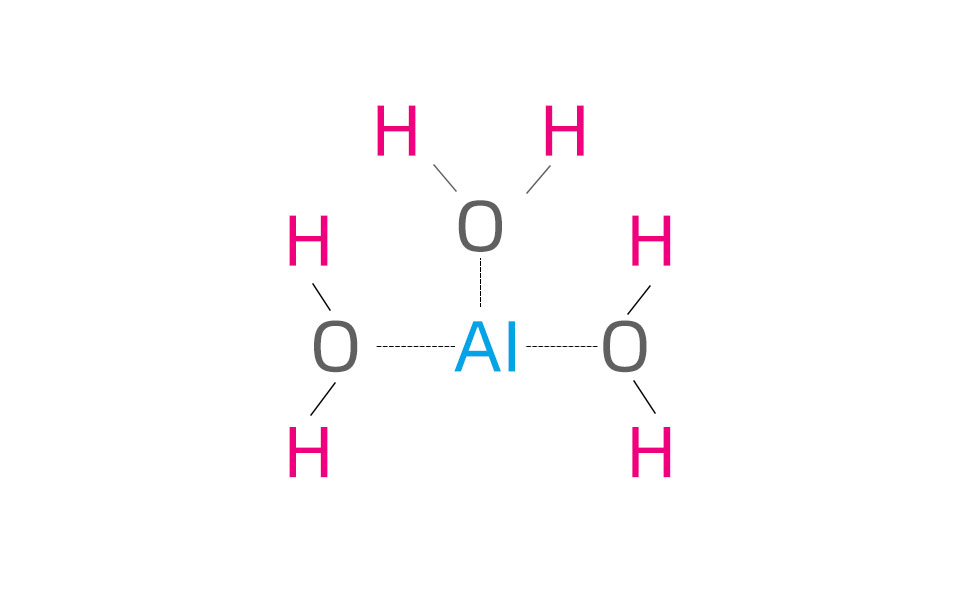

Aluminum hydroxide

Wet aluminium hydroxide materials are added into spin flash dryer through the screw feeder. Natural air passing through filter is compressed by the blower, and then enters gas furnace. It then enters

Contact us

Wet aluminium hydroxide materials are added into spin flash dryer through the screw feeder. Natural air passing through filter is compressed by the blower, and then enters gas furnace. It then enters the bottom air chamber of the spin flash dryer. Wet materials are being crushed by the dispersing device inside the spin flash dryer, and they are under heat exchange and drying with hot air at the same time. Dried materials and the exhaust gas are led through bag filter for separation. Exhaust gas is emitted from the top of the bag filter and released into the atmosphere through the induced draft fan. Qualified dried products are discharged from the bottom of bag filter and enter the packaging system.